Pulva Keeps You Running in Uncertain Times

This is a subtitle for your new post

Maintenance Issue: Purchasing the Correct Bearing

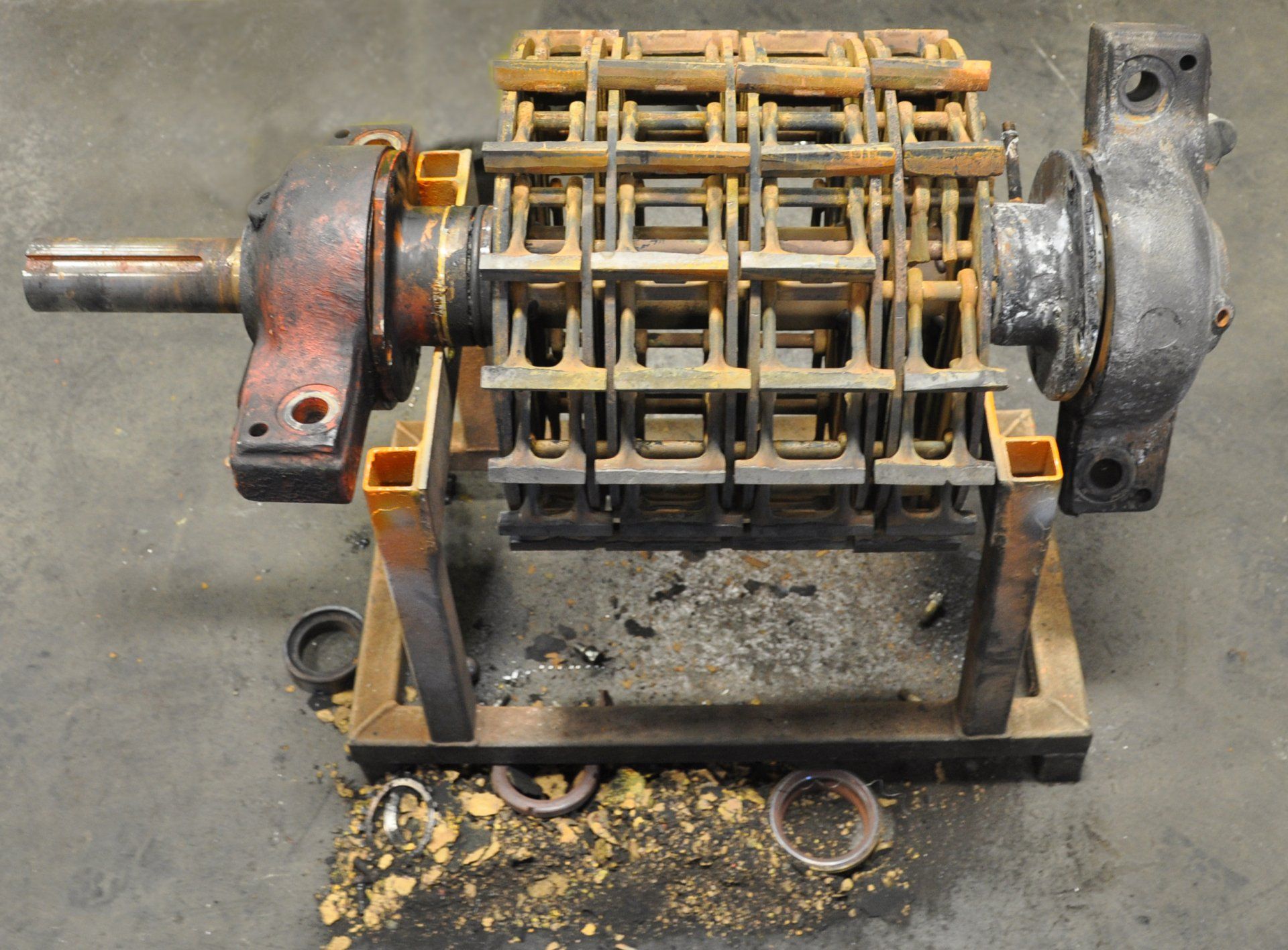

The heart of every hammer mill is the rotating assembly or rotor. Often spinning at 21,000 feet per minute, the rotor requires periodic maintenance. A crucial item in rotor maintenance is the bearings. When replacing bearings it is extremely critical that you directly replace a bearing’s class of fit and material of construction. Bearing suppliers have been known to substitute steel cage bearings for the Pulva recommended brass caged bearings. Even though steel caged bearings technically fit the application, Pulva customers have seen them fail in just a few hours.

If you aren’t sure what bearing your hammer mill rotor requires, click here for a quote. You might be surprised at how competitive Pulva’s bearing prices are.

Here’s a quick cross reference guide for Pulva bearing part numbers: