A Complete Guide to Toll Processing

Are you considering paying for toll process services? If so, you likely have questions about the benefits of toll processing, how it works and whether it is a good fit.

In this guide, we will explain the difference between contract and toll manufacturing, the advantages of working with a toll manufacturer and how to choose the right toll processing partner for your business.

What Is Toll Processing?

Toll manufacturers are a third party that takes material supplies and treats them to create a desired product. Some toll manufacturing examples include grinding, blending, coating, drying or packaging a product. Materials often treated by toll processors include carbon black, colored pigments, pharmaceuticals, food, fertilizer, recycling, spices, cannabis, grain and more.

Unlike contract manufacturing, toll manufacturers do not source the material they treat. Instead, they receive supplies from the original manufacturer and then take products to the next step as part of a larger production line. The term “toll” comes from the fee manufacturers pay for this service.

Benefits of Toll Manufacturing

There are many benefits to working with a toll processing manufacturer. Here are the top five to consider:

- Cost efficiency: Partnering with a toll manufacturer can save the cost of investing in specialized machinery and laborers.

- Professional experience: When you hire a toll manufacturer, you gain access to their years of experience and training.

- Quality control: One of the best benefits of working with a toll manufacturer is confidence in your product quality.

- Scalability: A toll manufacturer can handle a wide range of material loads, allowing you to scale up your business as it grows.

- Expanded services: With their equipment and expertise, toll manufacturers equip you to offer more to your clients.

If these benefits sound exciting to you, then outsourcing toll manufacturing may be the right choice for your company.

Contract Manufacturer vs. Toll Manufacturer

Toll manufacturers are a type of contract manufacturer, or a company that provides a paid service for the manufacturing industry. However, there are key differences between contract and toll manufacturers:

- Contract manufacturers source, purchase and treat materials for a manufacturing customer.

- Toll manufacturers process materials sent by a manufacturing customer. They do not also source materials.

When you work with a toll manufacturer, you can expect them to provide high-quality services that improve your product. However, it is your responsibility to source and send them the product that you would like them to treat.

What Is a Tolling Agreement in Manufacturing?

A tolling agreement is another term for working with a toll processing company. These agreements include several steps:

- You send raw materials to a third party, the toll processing company.

- The toll manufacturer treats materials as agreed.

- You pay them a toll for their work.

This kind of agreement benefits many manufacturers because it outsources specific tasks they cannot complete on their own.

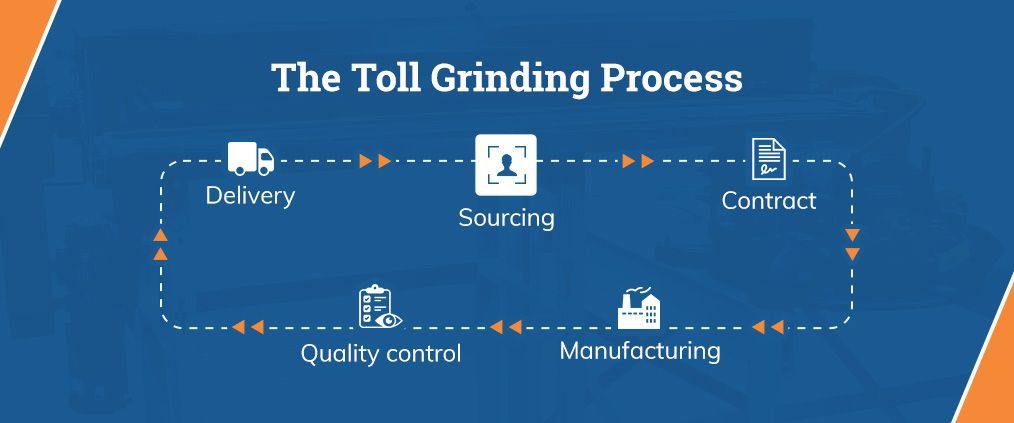

The Toll Grinding Process

Working with a toll manufacturer is simple. Before you contract with a company, always research their track record. Find out how past customers have felt and why they are a good fit for your needs.

Once you have chosen the right company, follow these basic steps:

- Sourcing: You supply the raw materials and production request to a toll processing company of your choice.

- Contract: Before work begins, you agree on terms like pricing, deadlines and quality standards.

- Manufacturing: The toll processing manufacturer treats your materials per the agreement.

- Quality control: Quality checks ensure your product standards have been met.

- Delivery: After work is complete, the toll processor will send the products back to you.

You can hire a toll processing company to complete a single step or many steps, depending on your product and the company's capabilities. For example, you might hire a toll manufacturer to dry materials, clean and reduce them with a wet slurry and then dry them again before delivery.

Types of Toll Grinding

There are three kinds of toll grinding, depending on the material that is being treated. They include dry, wet and cryogenic toll processing. Not every material breaks down with the same treatment, and different equipment is required for each kind of toll manufacturing.

Dry Toll Processing

This kind of treatment uses air to separate and treat materials. Dry processing is commonly used for products like minerals, metal ores, recycling and construction materials. It is also sometimes used to dry out materials during a multi-step process.

Because dry processing does not require wastewater disposal, it minimizes the environmental impact of material processing and is cost-effective. However, it does have limitations for particle size. If a material cannot be effectively separated by air, you can use wet or cryogenic toll processing to break it down.

Wet Toll Processing

As the name suggests, this type of processing uses water and other liquids to treat and refine materials. Wet toll processing is often used to treat precious metals, aggregates, industrial materials, recycled items and construction materials. Goals include washing, separating and concentrating materials.

Water is excellent for separating materials based on particle size, and it often leads to higher recovery rates of valuable materials than dry processing. However, it uses a significant amount of water. Managing the wastewater and slurries in an environmentally friendly way can be challenging and costly.

Cryogenic Toll Processing

This process uses cryogenic temperatures to make materials brittle, so they are easier to break down and separate. If materials do not respond well to dry or wet processing, they often will respond well to cryogenic processing. Materials commonly processed this way include thermoplastics, rubber, metals and pharmaceuticals.

Cryogenic toll processing creates quality products that are highly consistent. It can be used to treat many types of materials, and it works especially well for sensitive products like plastics and pharmaceuticals. However, the equipment can be costly, and it is a high-energy approach.

Choosing the Right Toll Processing Partner

Finding the right toll processing partner starts with knowing your needs. What kind of manufacturing tasks would you like to outsource? If you would like a third party to also supply your materials, it may be best to work with a contract manufacturer rather than a toll manufacturer.

Consider what kind of toll processing your material needs. Will it break down with dry, wet or cryogenic processing? Do you need the material to be dried, separated, ground or something else? You can speak with toll processing companies to determine what approach is the right fit for your product.

Before contracting with a company, always do research on their track record, expertise and quality control systems. It is not worth trusting your product to a toll processor who does not meet your standards for quality. Trustworthy toll processing manufacturers will be transparent about their pricing, capabilities and communication.

Find Toll Grinding Services at Pulva Corporation

Looking for size reduction manufacturing services? At Pulva Corporation, we have been serving the manufacturing industry since 1938. We are the leading global manufacturer of quality pulverizing equipment, and we also offer toll processing services. When you work with us, you can access the highest quality equipment, experienced employees and an excellent final product.

Our state-of-the-art equipment includes pulverizers, grinders, auxiliary equipment and replacement parts. We offer different types of grinders, including cryogenic grinders, depending on the materials you need to break down at our facility.

Contact us today to learn more about our toll grinding services and how they can support your manufacturing goals!