Pulverizing Mill Solutions

Pulverizer mills are mechanical devices that grind various types of materials, processing them in batches or through continuous acceptance on a conveyor. Commonly known as hammer mills, they rotate and press the bulk materials into desired states ranging from very fine to coarse depending on the degree of size reduction required. Some pulverizers even heat, cool or aerate materials as they exit the machine. With several types of pulverizing machines types on the market, these crushing solutions see use across many industrial fields.

Pulva Corporation has industrial pulverizing systems for sale worldwide designed to meet customers' size reduction equipment needs with a variety of milling technologies. We offer rebuild and repair services from our professionals, technical support and an extensive parts inventory to serve your needs and keep your company's downtime to a minimum.

Pulverizer Milling Applications

Industrial pulverizer hammer mills are designed to crush a comprehensive variety of solid materials ranging from soft to hard for size reduction needs from 6mm to 35 microns for optimal particle size distribution for a variety of milling applications.

Materials

When you purchase an industrial pulverizer grinder machine, you can expect to grind the following materials:

- Carbon Black

- Limestone

- Coal

- Clay

- Pigment Press Cakes

- Minerals

- Pharmaceutical powders

- Aluminum

- Concrete

- Cement Powder

- Recycling waste

- Polymer Industry

Industries

Because size reduction pulverizers are so varied in their material crushing capabilities, pulverizing equipment is widely used across many major industries for various particle size reduction needs. You can invest in a pulverizer machine specialized for your application-specific needs, no matter your industrial field.

Some of the primary industries that use size reduction pulverizers include:

- Construction

- Agriculture

- Manufacturing

- Power generation

- Pharmaceutical

- Landscaping

- Recycling

- Food processing

- Chemicals

- Metallurgy

- Mining

Hammer Mill Pulverizer Benefits

Investing in a laboratory or pilot plant pulverizer for your industrial facility means reaping all of the following operational benefits:

- Easy maintenance: Pulverizers from Pulva are easy to install and maintain, with removable door covers that enable greater accessibility for cleaning and wear part replacement.

- Energy conservation: You can achieve high-capacity grinding with minimal power consumption, with a pulverizer hammer mill, helping your company reduce energy costs.

- Zero dust pollution: Due to their fully sealed process capabilities, size reduction pulverizers prevent dust pollution.

- Variety of power and capacity: Pulva's line of pulverizers range from laboratory and pilot plant applications to industrial use, with models suited for operation with main drive motors ranging from 1-300 horsepower, and mill capacities up to 6,000 pounds-per-hour.

- Gravity feed and cryogenic grinding abilities: Pulva's hammer mills are capable of gravity feed and cryogenic grinding capabilities, offering extreme versatility in application.

Our Size Reduction Pulverizer Models for Sale

At Pulva, we offer a broad assortment of state-of-the-art pulverizers, ranging from laboratory and pilot plant to gravity feed models and everything in between. No matter your particle size reduction needs, we have the size hammer mill pulverizers to serve you and enhance your process capabilities. Explore our selection of high speed hammer mill crushers for sale below.

Model A Pulva Sizer 5-7.5 HP

The Model A is designed for continuous production work, but its small size makes it ideal for laboratory and pilot plant use. It is a complete unit with motors, starters, connections and is mounted on a portable stand with casters. It is equipped with either a 5 or 7.5 HP motor, and a 1-3/4” diameter feed screw with a variable speed drive mechanism.

The Model A is also available with an overhead feed screw arrangement which has a single 2-15/16” diameter feed screw for handling larger feed stock and can take a feed size up to 2”. A gravity feed model is also available which is recommended for high capacity grinding where fineness of grind is not priority. The Model A can also be set up for Cryogenic grinding to be used with our 3 ft cooling tunnel.

All Pulva-Sizers™ are capable of wet milling feed materials and slurries.

Pulverizer Product Specifications - Model A

LBS/KG

685 lbs / 311 kg

750 lbs / 340 kg

925 lbs / 420 kg

Dimension

----

43x36x66 in / 1.09x.91x1.68 m

48x39x67 in / 1.22x.99x1.70 m

Hopper Capacity

.51 CU.ft (STD) / 14442 CU.cm

Screen Area

44 Sq. In / 284 Sq. cm

Air Passed

Hammer Tip Speed

21,000 ft/min / 6,400 m/min

Rotor Dia.

8 in / 203 mm

Power

5-7 1/2 HP / 3.73 - 5.59 KW

Approximate Idle Load

1 1/2 hp / 1.12 kw

Pulverizer Product Specifications - Model B

LBS/KG

1,650 lbs / 748 kg

1,800 lbs / 817 kg

2,050 lbs / 930 kg

Dimension

64x60x36 in / 1.63x1.52x.91 m

64x62x48 in / 1.63x1.57x1.22 m

Hopper Capacity

1.0 CU.FT (STD) / 28317 CU. cm

Screen Area

118 Sq. in / 761 Sq. cm

Air Passed

150 CFM / 4.25 m3/min

Hammer Tip Speed

21,000 ft/min / 6400 m/min

Max Rotor Speed (RPM)

Rotor Dia.

12 in / mm

Power

10-25 HP / 7.46-18.64 kw

Approximate Idle Load

5 hp / 3.73 kw

Model B Pulva Sizer 10-25 HP

The Model B mill is equipped with a variable speed feed drive and is generally furnished complete and ready for operation with motors, starters, and wiring. Recommended for use with main drive motors ranging from 10 to 25 HP, depending on the material being ground. The standard feed arrangement is dual feed screws of 1-3/4”, 2-1/4” or 2-15/16” in diameter. The Model B hammers are available in stirrup or blade type.

The Model B is also available with either dual overhead feed screws or gravity feed. The gravity feed and overhead feed screw models are recommended for high capacity grinding where fineness is not a priority. The Model B is our most popular production mill for capacities ranging from 1000 to 6000 pounds per hour. The Model B can also be set up for Cryogenic grinding to be used with our 7ft cooling tunnel.

All Pulva-Sizers™ are capable of wet milling feed materials and slurries.

Model C Pulva Sizer 40-75 HP

The Model C is a relatively high-capacity compact mill. The rotor diameter is 18” and the grinding chamber is 14” wide. Recommended for use with main drive motors ranging from 30 to 75 HP, depending on the material being ground. The cover is hinged with a handle and 4 swing bolts which allow for quick access to the grinding chamber. The Model C can be either direct drive or belt driven and the dual feed screw arrangement can be supplied in either 2-15/16” or 4” diameter.

A gravity feed model is also available and is recommended for high capacity grinding of bulk materials where fineness of grind is not a priority. In the gravity feed model, the feed material falls into the grinding chamber, which can accept much larger lumps than the feed screw model. The Model C can have up to three times the capacity of the Model B and is the most popular configuration for Cryogenic grinding with one of our cooling tunnels.

All Pulva-Sizers™ are capable of wet milling feed materials and slurries.

Pulverizer Product Specifications - Model C

LBS / KG

3,100 lbs / 1406 kg

3,400 lbs / 1542 kg

3,600 lbs / 1633 kg

Dimension

85x63x40 in / 2.16x1.60x1.02 m

87x66x50 in / 2.21x1.68x1.27 m

Hopper Capacity

Screen Area

368 Sq. in / 2374 Sq. cm

Air Passed

450 CFM / 12.74 m3/min

Hammer Tip Speed

21,000 ft/min / 6400 m/min

Max Rotor Speed (RPM)

Rotor Dia.

18 in / 457 mm

Power

25-75 HP / 18.64-55.93 KW

Approximate Idle Load

12 HP / 8.95 KW

Pulverizer Product Specifications - Model D

LBS / KG

4,700 / 2132

5,100 / 2313

5,300 / 2404

80x89x50 in / 2.03x2.26x1.27m

80x89x50 in / 2.03x2.26x1.27 m

Hopper Capacity

2.5 Cu.FT (STD) / 70792 CU.cm

Screen Area

490 Sq. in / 3161 Sq. cm

Air Passed

600 CFM / 16.99 m3/min

Hammer Tip Speed

21,000 ft/min / 6400 m/min

Max Rotor Speed (RPM)

Rotor Dia.

24 in / 610 mm

40-125 HP / 29.83-93.21 KW

Approximate Idle Load

18 HP / 13.42 KW

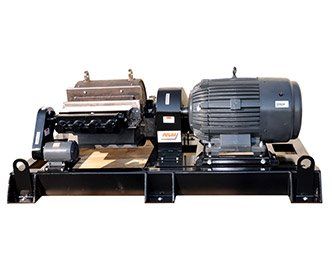

Model D Pulva Sizer 40-125 HP

The Model D is the workhorse of our line. Recommended for use with main drive motors ranging from 40 to 125 HP depending on the material being ground. The cover is hinged with a handle and 4 swing bolts which allow for quick access to the grinding chamber. The dual feed screw arrangement can be supplied in either 2-15/16” or 4” diameter.

A gravity feed model is also available which is ideal for grinding lumps up to 6” in size, depending on the nature of the material. Feed can be controlled by a chute or conveyor. The Model D can be either direct drive or belt driven.

Other feed arrangements include the horizontal feed opening designed for pneumatically conveying feed material and the vertical feed trough designed for gravity feed using our standard cover. The VT is used frequently in the carbon black industry. The Model D is designed for very high production and can be set up for Cryogenic grinding with one of our cooling tunnels.

All Pulva-Sizers™ are capable of wet milling feed materials and slurries.

Model F Pulva Sizer 125-300 HP

The Model F is a Pulva-Sizer™ designed for very high production of granular to medium-fine grinding and milling. It can produce 75% higher capacities than our Model D and can be driven by 125 to 300 HP. The unit is furnished with a multi v-belt or direct drive.

Due to the large volume of product involved, the Model F has a simple hopper feed design and air conveying outlet. The cover, liner and screen are designed for easy removal for maintenance and/or replacement. The Model F can also be fed with quad feed screws of 4” diameter or a gravity feed model is also available.

The Model F Pulva-Sizer™ produces grinds that can be exactly predetermined as on any of our smaller capacity mills. It is a high-speed, close clearance hammer mill that shares the efficiency and high thru put of the standard Pulva-Sizers™. The Model F is capable of wet or dry grinding, and can be supplied with a wide range of hammer and screen types. It is also available in stainless steel construction.

All Pulva-Sizers™ are capable of wet milling feed materials and slurries.

Pulverizer Product Specifications - Model F

LBS / KG

4,700 lbs / 2132 kg

5,100 lbs / 2313 kg

5,300 lbs / 2404 kg

Dimension

80x76x47 in / 2.03x1.93x1.19 m

80x89x50 / 2.03x2.26x1.27 m

2.5 CU.FT (STD) / CU.cm

Screen Area

840 Sq. in / 5419 Sq. cm

Air Passed

750 CFM / 21.24 m3/min

Hammer Tip Speed

21,100 ft/min / 6400 m/min

3,450

Rotor Dia.

24 in / 610 mm

Power

125-300 HP / 93.21-223.71 KW

Approximate Idle Load

25 HP / 18.64 KW

Pulverizer Product Specifications - Pulvette

LBS / KG

257 lbs / 117 kg

350 lbs / 159 kg

375 lbs / 170 kg

----

26x30x44 in / .66x.76x1.12 m

33x33x45 in / .84x.84x1.14 m

.11 CU.FT (STD) / 3115 CU.cm

Screen Area

7.8 Sq. in / 50.3 Sq. cm

Air Passed

10-15 CFM / .28-.42 m3/min

Hammer Tip Speed

21,000 ft/min / 6400 m/min

Rotor Dia.

5 in / 127 mm

Power

.75/ - 1.00 HP / .56-.75 KW

Approximate Idle Load

.5 HP / .37 KW

Pulvette Pulva-Sizer 3/4 - 1 HP

The Pulvette Pulva-Sizer™ is our laboratory unit, ideal for small manufacturers and pilot plant operations and is an excellent blending and dispensing unit. The Pulvette has a 1HP main drive motor and comes equipped with a 7/8” diameter feed screw. The rotor assembly comes standard with six forged “T” style hammers and Blade style hammers are also available as an option. It is accessible, easy to clean, and is manufactured to the same precision standards as our larger Pulva-Sizers™.

A gravity feed model is also available and is recommended for larger feed materials. Machine dimensions are approximately 2’x2’x 4.5’ high. Other styles include a vibrating model as well as a branch model which is ideal for test facilities.

All Pulva-Sizers™ are capable of wet milling feed materials and slurries.

A Leading Pulverizer Machine Manufacturer

For over 80 years, Pulva Corporation has specialized in delivering top-quality particle size reduction equipment, parts and services to customers across industries. From supplying pulverizers for the recycling industry to serving the pharmaceutical sector, we have earned a reputation as a premier hammer mill manufacturer.

Our family-owned business has served as a global industry leader in pulverizing machines since our establishment in 1938. We have achieved tremendous growth and success over the last five years due to our knowledgeable and experienced staff, advanced manufacturing equipment, top-of-the-line facilities, and commitment to research and development.

FAQs About Pulverizing Mill Solutions

What's the Difference Between a Pulverizer and a Hammer Mill?

Since the word “pulverizer” is an umbrella term for size reduction equipment, there's no real difference between a pulverizer and a hammer mill. A hammer mill is a specific type of pulverizer that's used for various applications, including:

- Grinding food products.

- Breaking down recyclables and scrap material.

- Producing fine powders for pharmaceuticals.

How Do I Choose the Right Size Pulverizer for My Application?

To choose the right size pulverizer for your application, consider the following factors:

- Material type

- Desired particle size

- Production volume

- Manufacturer preferences

Consulting with manufacturing experts like the team at Pulva can give you valuable insight into which machine might be the most suitable option for your application. Contact us to discuss your size reduction needs.

What Materials Cannot Be Processed in a Pulverizer?

Combustible materials such as certain plastics, spices and organic materials cannot be processed in a pulverizer without adding liquid.

Pulverizers generate high amounts of friction, which creates a hot environment with an abundance of dry air. Volatile compounds exposed to these conditions can cause sparks and, potentially, fires. Wet pulverization is a technique that enables you to safely process these materials while improving your overall energy efficiency.

If you have any questions about which materials you can and cannot process in a pulverizer, feel free to reach out to an expert for more information.

What Industries Benefit Most From Using Your Pulverizing Solutions?

Our pulverizing solutions benefit companies across various industries with size reduction needs. The specific industries Pulva serves include:

- Pharmaceuticals

- Powder coating

- Food processing

- Recycling

- Plastics

- Grain

- Cannabis

- Fertilizer

- Spices

- Cosmetics

- Colored pigments

- Carbon black

We can also recommend specific machines and size reduction services for industries not on this list. Contact us to discover powerful pulverizing solutions for your industry and application.

Find High-Quality Hammer Pulverizers for Sale Today!

You can purchase state-of-the-art gravity feed hammer pulverizers and more from Pulva Corporation. We are dedicated to raising the bar for longevity and performance through our dependable products, parts and services.

Request a custom quote for your pulverizing equipment needs today!