Partnering for Cost Reduction

This is a subtitle for your new post

Partnering for Cost Reduction

Late in 2017 Pulva Corporation was requested to attend a customer initiated “Grinder Improvement Meeting”. During the meeting the customer presented Pulva engineering and sales with data from component break in periods and component life cycle. At the time component life was 19 continuous days of operation. The component life cycle was determined by particle size output from the grinder. Once particle size grew to an unacceptable oversize condition all major grinder contact parts were changed regardless of wear amount. The customer emphasized that multiple shutdowns per planned running cycle was not favorable and that it proved more cost effective for scheduled outages at predetermined times. At that time 450 hours of operation (19 days) was the set bench mark.

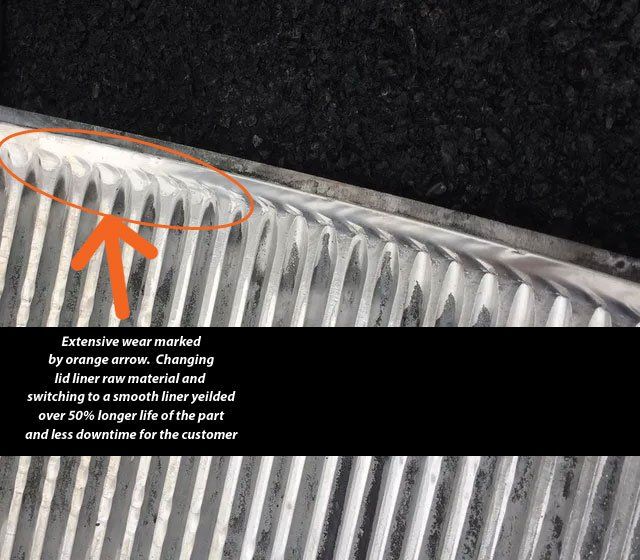

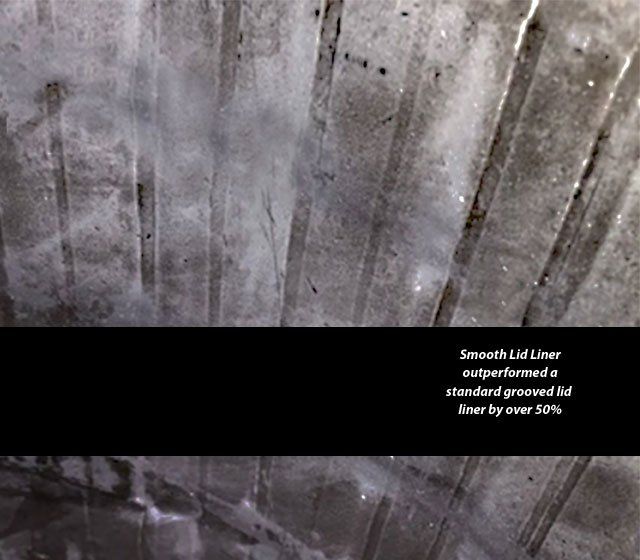

Pulva immediately recognized 2 potential issues. One with the lid liner while the other was with the screen. Screen modifications were trialed first. The break in period for the grinder definitely stabilized with the screen modifications. Next lid liners were trialed and a smooth liner was determined to potentially yield longer life. After multiple individual trials (screen and lid liner) it was determined that the results were promising enough to trial both components together. The cumulative trial resulted in 29 days (700 hours) of continuous operation!

Using prior project success the customer suggested a change in materials used for construction. Once again Pulva manufactured test screens and lid liners from the advanced material suggested by the customer. Currently it has been determined that the life cycle has improved to over 41 days (1000 hours).

The customer reports: “we have achieved a first: over 1000 hours of operation at near maximum rates.

This is a great accomplishment, and it is the gold standard right now”.

Dialogue continues into 2021. New potential cost savings issues are being discussed. The focus has been extending the time between shutdowns. It will likely change to shortening the amount of time to execute a changeover.

Contact Pulva today with your component issues. Put our team to work for your bottom line!

Changing Style and Material of Lid Liner Gained over 200% Life of Part