Paint Dispersion Mixers

Browse high-speed dissolver equipment from Pulva Corporation. Our experienced engineers will develop a unique dispersion system for your business and optimize it to your industry's needs. Request a quote for Pulva Corporation to build a custom high-speed disperser for your unique business requirements.

Pulva Dispersion Mixers

Pulva Corporation offers a high-speed disperser for paints. Our five-in-one dispersion mixer reduces production time by as much as 90% by applying high-energy force to impellers and miniature beads. The subsequent vortex grinds dry ingredients into micron-sized particles that disperse into the chosen fluid. This dispersion method achieves the ideal viscosity and pigment.

For additional efficiency and value, these systems offer modification-free process shifting. Your operator can move from dispersion to tinting as soon as the process completes, bypassing the need to discharge the mixture or adjust the drive. Our system enables let down up to vessel capacity.

Our mixers leverage powerful turbulent force ideal for blending low-viscosity batches with various solid substances. They also accept water and oil base formulas for sand mills and ball mills.

Dispersion Mixer Applications

Dispersion mixers blend powders into liquid and merge solvents, which is a critical process in numerous industrial applications. Dispersers are common in paint production to add pigmentation to any solvent.

We produce dispersion mixers specifically for paints. Use our dispersing equipment to produce premium paints with rich pigmentation and complete texture control.

Pulva dispersion mixers offer three performance levels, each ideal for specific pigments. Your business will achieve high production speeds when working with various types of pigments:

- Fast-grinding pigments: Disperse ferrites, oxides and other fast-grinding pigments in 20 minutes.

- Medium- to hard-grinding pigments: Disperse chrome yellows and greens in 30 minutes.

- Hard-grinding pigments: Disperse CPC blues, greens, blacks and maroons in 45 minutes.

Epworth SW Mill by Pulva Features

Our machines empower disperser operators to perform at peak efficiency while producing accurate mixtures. We design our dispersion mixers within the optimum specifications for paint production. The standard features available with our dispersion mixers offer a few key advantages that improve efficiency and production speed.

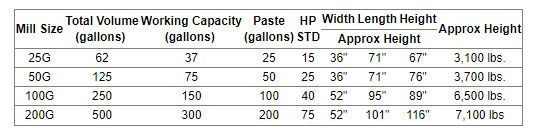

Pulva dispersion mixers are available in various sizes. Choose a dispersion mixer with a mill ranging from 25 to 200 gallons and a total volume from 62 to 500 gallons. These dispersers function at an operating viscosity between 50 to 115 kilo units, maximizing the life span of the vessel, impeller and media.

We design these systems for fast, easy cleanup. The mill discharges the entire solution after dispersion, facilitating a quick transition to the next batch. Additionally, we design our dispersion mixers to limit maintenance requirements.

Each disperser features a single belt with two sealed bearings. This configuration bypasses features like gears and pumps that clog and require frequent lubrication.

To bolster durability, parts subject to abrasion feature strong steel alloys that withstand lengthy operation periods. Such parts are easily replaceable with new EMCO units to minimize downtime.

We offer various optional tools to augment your dispersion mixer. Outfit your system with optional equipment such as chilled white iron rotors, wear-resistant ceramic tiles, ammeters, magnetic motor starters with overload protection, temperature control devices and more.

Optional Equipment

HC-250 Rotors extend the life of rotors up to 10 times. Manufactured from chilled white iron so hard that machining cannot be accomplished using tungsten carbide cutting tools. Rotors are precision ground with abrasives to finished size.

Wear resistant ceramic tile. Special tiles are bonded to the vessel wall in the wear zone. Tile replacement can be accomplished in the field with customer's personnel, extending vessel life indefinitely. [Rotor(s) removed to reveal tile.]

Ammeters are mounted in explosion-proof enclosures with large glass window for easy viewing. Installation includes explosion-proof connections and transformer. Internal wiring is connected completely when starter is also ordered.

Motor Starters are contained in explosion-proof enclosure in combination with circuit breaker disconnect. Starters are full voltage, across the line, magnetic type with overload protection for all lines. A separate start-stop station is provided. All components are mounted and completely wired ready to receive customer's primary power from the plant's system.

Other Options:

Automatic discharge valve actuators - Multiple station controls - Hour meters - Elevating sub-bases - Platforms and hand rails - Sealed cover

Temperature control devices are available to automatically meter cooling or heating medium through the mill jacket to control batch temperature. Temperature devices are either explosion-proof electrical or nonelectrical mechanical units, safe in hazardous atmospheres.

Request a Quote From Pulva Corporation

Pulva Corporation has over 80 years of experience developing premier industrial equipment such as paint dispersion machines. Our custom-built solutions will enhance production processes by providing powerful equipment to your skilled operators. For more on our dispersion systems, features and optional equipment, please request a quote today.